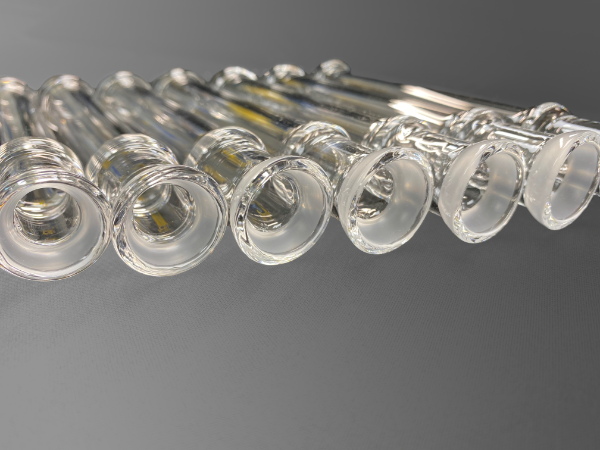

High purity quartz glass accessories

We have established ourselves as the industry leader, providing high-quality fabricated quartz glass for a wide range of applications. Whether you need glass components for optical fiber manufacturing, life science applications, medical equipment, or any other industry, we are your trusted partner.

Our key capabilities in quartz glass fabrication

CNC Machining: Our advanced CNC machining capabilities allow us to precisely shape and manipulate quartz glass components according to custom designs. With the help of computer-controlled machinery, we can achieve complex geometries, tight tolerances, and exceptional surface finishes.

Hot Forming: Hot forming is a process used to shape quartz glass at elevated temperatures. By carefully applying heat and pressure, we can achieve precise geometries and produce components with excellent dimensional accuracy. This technique allows us to create intricate shapes that are otherwise challenging to manufacture.

Inner Diameter Reduction: We utilize specialized hot working techniques, tools, and equipment to reduce the ID and form designated profile shapes of quartz glass components. This allows us to achieve custom dimensions and precise tolerances, ensuring a perfect fit for your specific application requirements.

Welding: Quartz glass welding is the process of joining two or more quartz glass pieces to create larger, more complex structures. We utilize various welding methods, to ensure a strong, reliable bond between quartz glass components. Welding enables us to construct sealed enclosures and custom assemblies.

Fire Polishing: Fire polishing is a specialized technique used to enhance the optical clarity and surface quality of quartz glass. By subjecting the material to high temperatures, we can smooth out any surface imperfections, resulting in a clear and flawless appearance.

Centerless Grinding: We employ centerless grinding techniques to refine the dimensions and surface finish of quartz glass parts. This process enabling us to achieve precise diameters and concentricity. Centerless grinding is particularly suitable for manufacturing cylindrical components such as tubes and rods.

We are leading in highly efficient, large scale production of customer specific complex glass parts

At our facility in Wilmington NC, we leverage the principles of lean manufacturing and automation to deliver high-quality products efficiently and effectively. Our lean manufacturing and automation practices play a pivotal role in achieving maximum efficiency and value for our customers.

Our fabrication facilities are equipped with cutting-edge automation technologies for enhanced precision, speed, and consistency in our manufacturing processes. Our capabilities in machining and hot working enables us to meet the diverse needs of our customers. Our skilled craftsmen utilize their expertise and experience to transform the molten quartz glass into a wide range of products, including assemblies, handles, burners, ampoules and more.

With our advanced fabrication capabilities, unrivaled expertise, and commitment to quality, we can provide you with quartz glass solutions that meet your exact specifications.